Aug 6, 2009

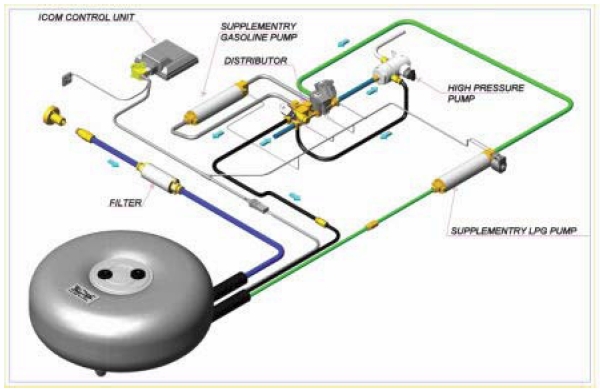

A patent-pending high-pressure direct-injection system delivers liquid propane by exploiting key components of directinjection gasoline fuel delivery apparatus.

In a bifuel configuration, an adapter applied to the pump handles the injection process after a distributor directs gasoline to the tank and liquid propane is sent to the high-pressure pump.

“From the high-pressure gasoline pump, the liquid propane is injected into the combustion chamber using the same gasoline hydraulic circuit as the original gasoline injectors at the pressure established by the vehicle manufacturer,” explained Ralph Perpetuini, CEO of Icom North America, the U.S.-based affiliate of Italy’s Icom S.p.A.

Icom’s high-pressure direct-injection process unfolds at approximately 180 bar (2611 psi) vs. the seven to eight bar (101 to 116 psi) of a normal liquid propane injection process.

“The Icom JTG hp direct-injection system is exclusively for direct-injection engines that inject fuel in the combustion chamber at high pressure,” said Perpetuini. “In contrast, the Icom JTG liquid injection system is for indirect-injection engines that inject fuel in the manifold at relatively low pressure and require an additional set of injectors for the propane injection on a bifuel system.”

The monofuel configuration uses one set of injectors.

Start of production for the JTG hp is slated for the fourth quarter of 2009. “We have to finish up homologations to make sure all of the components are LPG-compatible and that the homologations are correct,” Perpetuini noted. “And of course, we have to finish up testing for reliability as well as do final testing.”

In the meantime, Icom North America is focused on production. The company plans to hire additional engineers and production staff as it works to domesticate the liquid propane injection system. The objective is to almost reach 100% local production.

“We’re at about 50% right now with what is assembled by our licensee, Sleegers of London, Ontario, Canada and what is done in New Hudson, Michigan,” Perpetuini said, noting that multivalves, pressure regulators, and injection rails are currently produced in Italy and shipped to North America.

In addition to liquefied petroleum gas (LPG) injection systems, Icom North America’s products include toroidal (donutshaped) and cylindrical LPG tanks as well as compressed natural gas (CNG) systems for commercial and passenger vehicles. Icom customers in the U.S. include Roush (Roush-Ford F-150 and F-250 propane-fueled pickup trucks) and Blue Bird (propane-fueled school buses through CleanFUEL USA).

To demonstrate that any gasoline or diesel-powered vehicle can be modified to use propane, Icom North America and CleanFUEL USA of Texas converted a Saturn Vue gasoline-electric hybrid to a propane-electric hybrid. The Vue propane-electric hybrid was shown at the 2008 SEMA Show and the 2009 Chicago Auto Show.

“The U.S. currently has more than 170,000 propane-fueled vehicles. We expect that number to rise as consumers of commercial and passenger vehicles fully grasp the cost and environmental benefits associated with LPG,” said Perpetuini, adding, “Icom’s existing JTG system and its forthcoming JTG hp system are designed to function in harmony with OEM gasoline engines as a fully integrated system.”

Author: Kami Buchholz, SAE International